Savage FAQ

Frequently Asked Questions:

X. New Important Note Regarding Barrels. (Added Jan '04)

1. What Savage Rifles are suitable for customization?

2. What features make the Savage 110 suitable for customization?

3. What are the undesirable features of the Savage 110 family of rifles?

4. What is the Savage 110 barrel thread size?

5. Who designed the Savage 110 action?

6. What tools are required to remove a factory Savage 110 barrel?

7. The Savage 110 Action Vise is expensive. Can I do without it or make a suitable one myself?

8. How are rifle barrels refurbished?

9. Why are so many of the refurb barrels offered for sale Remington barrels?

10. When installing barrel that uses the lock nut to what headspace should the barrel be set to?

11. Can barrels using the lock nut be used for a switchbarrel rifle?

13. Is it so simple to swap barrels on a Savage 110 that anyone can do it?

14. What tools are recommended for installing barrels using the lock nut.

15. What tools are recommended for installing short chambered barrels.

- What Savage center fire rifles are suitable for

customization?

The Savage Arms Company introduced the Savage 110 rifle in 1957. The original rifles were mechanically very similar to the Savage Rifles produced today except for the breaching system. The original system was similar to that of the Remington 700 with the barrel having a recessed breach that the bolt nose extended into. Savage advertised their rifle as protecting the shooter by surrounding the case head with three “rings of steel” – the barrel recess, bolt nose and the action.

Starting around 1967 Savage changed the 110 barrels so that the barrel ends were flat, with minimal head clearance similar to a Mauser breech. It is these rifles that parts and barrels are readily available and are the most suitable for customization.

In the last few years Savage has introduced several new versions of the 110, most notably short action versions (Model 10) and both long and short action single shot versions. Critical parts are interchangeable with the 110s. However, most recently Savage introduced a modified version featuring a larger barrel thread diameter, improved adjustable trigger and controlled round feed (CRF), for use with the new short magnum cartridges. Customization options for these rifles are more limited.

Top of the Document - What features make the Savage 110 suitable for

customization?

· Low cost. If you want to start with a new action, complete rifles can be bought at a chain store for a reasonable price. Used rifles can be had for as low as $200 for a serviceable long action gun in 30-06 or 270 (calibers now out of fashion).

· Barrel Nut. Savage uses a barrel without a shoulder, chambered and threaded. To fit the barrel to the action the barrel is screwed in against a gage and barrel nut tightened to lock the barrel in place. This is done as an expedient – the barrels don’t have to be chambered/dimensioned with high precision tolerances. To the customizer it means that a new or refurbished barrel can be fitted without the use of a lathe or even chamber reamers.

· Left hand versions are readily available.

· Two piece bolt. Savage rifles utilize a bolt with a separate bolt head, again as a manufacturing expedient. (It is easier to machine, heat treat and temper the smaller bolt head rather than an entire bolt.) However, these bolt heads are also more inexpensive for a customizer who wants to rebarrel to a caliber with a different bolt face or a shooter who wants a switchbarrel rifle using calibers with different bolt faces (e.g. 223 and 308).

· Strength and Safety. The 110 can safely be chambered for any caliber, including any of the new short or ultra magnums. In the event of a blown primer or case head separation gases are vented away from the shooters face.

·

Top tang safety. Its convenient, three position (so you

can unload on safe) and quiet.

Top of the Document

- What are the undesirable features of the Savage 110

family of rifles?

The following features are drawbacks of the 110 design.

· Trigger. Because of the limited mechanical advantage (the trigger bears against sear which is bearing against the main spring) the factory trigger cannot be safely adjusted below 3-5 (experts vary) pounds. After market triggers do better but the placement of the sear forward of the trigger make design of low pull weight triggers problematic. See the Savage Trigger page for more on the design and adjusting of the Savage trigger.

· Firing Pin. Some like the fact that pin protrusion is adjustable (something else to experiment with) and the fact that the pin assembly is light is thought to contribute fast lock time. In reality, lock time is poor because of the additional mass of the “sear-cocking indicator-bolt release” (which must be dragged forward) and because of firing pin friction. The friction is due to tight clearances between the firing pin and bolt body, including where the firing pin is used to retain the bolt head pin. The tight clearances promote safety by blocking escaping gases but as a result 110s are known to misfire due to debris or (at low temperatures) grease accumulating in the bolt body. See the Savage Firing Pin page for instructions on adjusting the firing pin.

· Action Stiffness. Due to length, generous cutouts for magazine, the placement of the rear action screw and the size of the trigger assembly there is limited action surface for bedding and the action itself is not considered stiff enough for serious target shooting (e.g. benchrest shooting). As a result if you want one of the single shot rifles you can expect to pay quite a premium.

·

Action Length. The long action is long with

a bolt throw longer that other similar actions. If you want one of the short

action rifles you can also expect to pay a premium.

Top of the Document

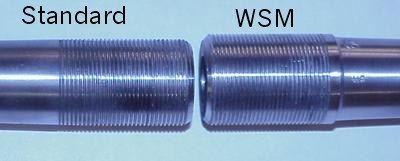

- What is the Savage 110 barrel thread size?

Until recently all the Savage rifle barrels were threaded with 60 degree V-Threads at 20TPI with a thread diameter of 1.05”. The new CRF short magnum actions are threaded 20TPI but with a thread diameter of 1-1/16”.

Added January 2004 - See Important note regarding new Savage Barrel Threads abve.

Top of the Document - Who designed the Savage 110 action?

Detractors may answer Rube Goldberg, but the designer of the Savage 110 was Nicholas Brewer He also designed the Savage 340 rifle which also used a barrel nut for headspacing.

Top of the Document - What tools are required to remove a factory Savage 110 barrel?

We recommend the following items. Note that a barrel vise and action wrench can be substituted for the action vise listed below. We recommend the action vise because it protects action components, acts as a heat sink and us handy for other action work such as installing receiver sights. With the action mounted in the vise, the factory barrel can almost always be turned out by hand once the barrel nut is loosened.

· Barrel Nut Wrench

· Savage 110 Action Vise

· C-Clamps to attach action vise to a sturdy bench.

·

Heat source (heat gun, propane torch, etc) to break

thread sealant.

Top of the Document

- The Savage 110 Action Vise is expensive. Can I do without

it or make a suitable one myself?

It is not difficult to remove the barrel from a Savage. The ‘trick’ is to use heat to break the thread sealant. Using a large bench vise and some hardwood to hold the action in the vise you should be able to remove the barrel without scratching anything if you have a barrel nut wrench. If you don’t care about scratching the barrel and/or nut you can use a pipe wrench.

You can make a quite suitable action vise out of hardwood, and a couple of bolts only be careful if you are using heat to break the sealant on a factory barrel. Plans to make one out of wood are here.

Top of the Document - How are rifle barrels refurbished?

Rifle barrels wear mainly in two areas – the chamber throat area and the crown. The throat erodes due to the high temperature flame from the burning powder and the swaging of the bullet into the rifling grooves. Crowns are usually damaged during cleaning. Refurbished barrels have at least 1 inch cut off from the chamber area, and the chambers are extended using piloted reamers in a floating holder. Threads are extended or cut on a lathe with a single point threading tool. Crowns are cut to 11 degrees either on the lathe or with a piloted tool.

Note that even new factory barrels benefit from straighter chambers and threads that are squared up to the barrel axis.

Top of the Document - Why are most of the refurb barrels offered for sale Remington

barrels?

As stated on the Remington 700 FAQ page, the Remington 700 has several design features that make it easy to build a highly accurate target rifle. As a result, most people setting out to build a target rifle will start with a Remington 700 rifle. Since the barrel has to be removed to work the action, most target shooters will spring for a custom barrel. The “take off” factory barrel then goes on the market (e.g. Ebay). While factory barrels are not suitable for something like benchrest shooting, they are more than accurate enough for most hunting and with a re-cut chamber and crown many are suitable for general target shooting.

Top of the Document - When installing barrel that uses the lock nut to what headspace

should the barrel be set to?

If your rifle is going to be used for target shooting, you want a minimum headspace chamber. The barrel should be turned against a GO chamber gage and the barrel lock nut tightened. The bolt will probably not even begin to close on a NO-GO chamber gage. This will minimize case stretching and result in long life for your reloaded cases. (Keep those cases trimmed below maximum!)

Hunters who may be hunting under harsh condition, or maybe firing a lot of rounds between cleanings may want a chamber with more room to insure rounds will always chamber, even if the gun is dirty. Then the bolt should be turned tightly against a NO-GO gage and the barrel nut tightened. The barrel should be kept tightly against the gage to insure all the spring is taken up, and the bolt should close with some resistance on the NO-GO gage. You must check to insure that the bolt will not close on a FIELD gage!

For most, the optimum is that the bolt closes easily on a GO gage and will not close on a NO-GO gage. This can be done by putting alternately tightening the barrel against GO and NO-GO gages and keeping the barrel somewhere in between when tightening the barrel nut. This can be aided by the use of a witness mark on the barrel matched with a witness mark on the receiver.

Top of the Document - Can barrels using the lock nut be used for a switchbarrel

rifle?

There are some who swap barrels just by lining up witness marks on the barrels with a mark on the receiver. When we tried this we had problems. (Which is why we started playing with lathes and Remington “take off” barrels.) It was very frustrating to go to the range only to find that the neck sized reloads wouldn’t chamber, or a shot at the hunter benchrest sighter hit one of the record targets after a barrel change. It was just too difficult to headspace the barrel accurately enough that it shot close to where it did before. These problems went away when we fitted barrels with shoulders that we could just turn in and tighten with a wrench.

Through experimentation we found we could get similar results by tightening the barrel hard against a GO gage. However, chambering got difficult after the gun got dirty (especially shooting cast bullets!). That is why we came up with a SET-TO gage. This gage is for a headspace midway between GO and NO-GO. With a SET-TO gage you can turn in the barrel tight against the gage, tighten the barrel nut and get the barrel back to the same position each time it is switched.

Some claim to have used a fired case as a SET-TO gage. We found cases too “springy” to insure the barrel got tightened in exactly the same position. You can make your own SET-TO gage by shaving off 1-3thousands from a NO-GO gage.

Top of the Document - Why should I remove the barrel and measure receiver ring

to bolt face distance before ordering a short-chambered or try-fit barrel?

Savage changed that dimension several times over the years. Measuring is the only way to insure you can get a barrel that can be fitted/chambered for your rifle.

Top of the Document - Is it so simple to swap barrels on a Savage 110 that anyone

can do it?

No. First of all, anybody who attempts this should have a good idea what they are doing. They need to know and understand what clearance and headspace is. Better than average dexterity with tools is required. Tools as noted above and below are needed and a safe place to remote test (e.g. mount rifle on bench and fire with a string) is needed.

If you’re the kind of guy who takes your car in for brake service, you probably want a local gunsmith to build your switchbarrel rilfe or change calibers. Since you are paying for the labor you will probably want a custom barrel from Shilen, Lilja, or Douglas. We sell parts and tools for our fellow do-it-yourselfers.

Note: Virtually every firearm manufactured is remotely (i.e. isolated from firer) test fired after assembly. Even with the multiple quality checks, and CNC machining to tight tolerances it is still considered too dangerous to use a rifle with a newly fitted barrel without test firing first. GUNS ARE DANGEROUS.

Top of the Document - What tools are recommended for installing barrels using

the lock nut.

The following are needed:

· Savage Barrel Lock Nut wrench

· Savage 110 Action Vise (or other suitable means to hold action).

· Pair of chamber headspace gauges (GO/NO-GO or SET-TO/NO-GO or NO-GO/FIELD)

· Measuring tools for measuring receiver face to bolt distance to order correct barrels.

· Savage 110 Action Vise (or other suitable means to hold action).

· Pair of chamber headspace gauges (GO/NO-GO)

· Barrel wrench (or large Crescent wrench for switchbarrel guns).

· Finish chamber reamer with extension handle.