The first Savage I ever bought was a 110C for deer hunting which I bought for two reasons. These two reasons were a direct improvement over the lever gun I had hunted previously with - a silent 3 position safety and a detachable box magazine. Hunting on public lands means starting out and ending the hunt out in the woods, in the dark. The clip mag is a big improvement over fumbling rounds in the dark. The 110 magazine system works really well, being spring loaded so that magazine pops out when the release is pushed. The only problem is that stock options are more limited, as most after market Savage stocks are for the blind magazine version. When using the 110 as a switchbarrel target gun, I just removed the magazine holder from the action and used it as a single shot with stocks for the standard Savage action.

I decided to purchase a Choate Folding Stock for my Savage 110, to use not only as a deer hunting gun, but as a "car gun" for just in case use (I don't own a truck). The cheapest online pricing I could find was on www.combatstocks.com. I was thinking I could modify the stock to work with the magazine holder for the 110C. I was pretty surprised that the width of the stock is way too thin to accomodate the magazine holder. I needed to come up with something else to provide the detachable magazine capability. What I came up with was a modification to accept box magazines used with the Remington 788 rifles.

I was pretty much resigned to using a short action caliber (.308) as magazine options are more limited with 30/06, and space in the magazine well is somewhat limited. I also figured that a magazine that could fit and would be easy to make work would most likely be single stack. Some options I looked at included CZ and Tikka magazines. The problem with these is that the magazines are held in place by a close fitting magazine well and a spring loaded catch built into the well.

In comparison, the 788 magazine floats in the well being held in place by machined guide bar that slides into the back of the magazine. The magazine release, which engages the bottom of the guide, is built into the magazine. The magazine guide bar is avalable from www.gunpartscorp.com and the magazines are available from www.jocoemprise.com. So all I had to do was open up the bottom of the Choate stock to accept the magazine and figure out how to mount the magazine guide to the back of the magazine well.

Push feed rifles work best with the magazine releasing the cartridge with the cartridge as far forward (i.e. the round just entering the chamber as the feed lips release the cartridge) as possible. I therefore openned up the bottom of the stock with a slot for the magazine, starting just at the very front of the mag well. I did it by drilling a series of holes along the center line of the stock and then connected the holes using a jig saw. Fortunately, the bottom of the stock is just plastic. Once a slot was made I kept openning up the slot with a file until the magazine just slid in. That left a little less than 1 inch of bottom at the rear of the magazine well. I decided to afix an aluminium block at the back of magazine well to mount the magazine guide bar.

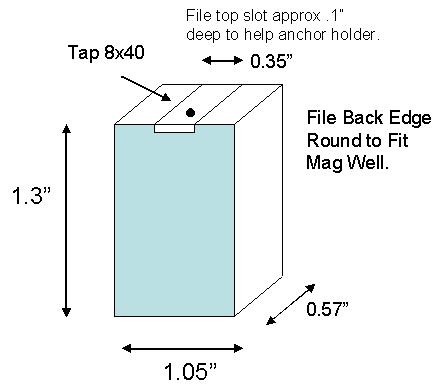

To provide a rigid base for the guide bar I cut a piece of aluminium stock (readily available at your local scrap dealer, or from ebay) the same width as the magazine well. What you are looking for is a tight fit at the back of the well. That turned out to be slightly less tha 1.05" wide. (What I recommend is cutting oversize and filling to fit.) However, the back of the well is slightly tapered and the corners are rounded. It is therefore required to file the sides and corners of the mount round towards the back to fit the very rear of the magazine well.

The guide bar consists of an L shapped steel stamping with a single hole for mounting. To provide rigidity I filled a slot equal to the width of the top part of the guide bar so it wouldn't wiggle/unscrew with a single 8x40 screw holding the bar in place. The slot turned out to .35" wide and only needed to be about 0.1 inch deep to provide a rigid mounting of the guide bar. The guide bar screw hole was placed to provide clearance for the magazine. That turned out to be 0.12 from the front edge of the mounting block. Once the guide bar was mounted at the top of the block I determined the hieght of the block by putting the magazine onto the rail and determining the heiight of the block that would put the magazine feed lips just below the bolt. That turned out to be 1.3" high.

I originally set the depth of the block equal to the top length of the guide bar. That turned out to be too deep not providing enough room the the magazine. I had to reduce the depth to 0.57" and grind the end of the bar to fit in that same space.

My original plan was to epoxy the mounting block into place and anchoring it with a single screw through the bottom of the magazine well. As it turned out the choate stock was thicker and deeper than the stock on a 788. I had to lengthen the slot to accomodate the magazine release as well as the body of the magazine. The screw mounting prevented me for lengthening it further for easier finger access to the magazine release. If I were to redo it I would arrange for anchgoring screws through.the sides of the stock. When I was finished the length and width of the slot cut into the bottom was 3.45x0.65". As shown in the accompanying photos, one nice feature is that the magazine doesn't protrude below the stock to snag on anything.

In checking feeding, it semed that the bullets were scraping along the bottom of the chanber lip as the magazine feed lips release the cartridges. I bent the guide bar up a little, and beveled the front of the magazine opening to allow the magazine front to raise up a little. After that feeding was perfect, even with round nosed factory 150 grain bullets.